Just How an Optical Fibre Diameter Analyser Improves High Quality Control in Fibre Manufacturing

The assimilation of an Optical Fibre Diameter Analyser into Fibre manufacturing procedures represents a substantial development in high quality control techniques. By providing real-time, exact dimensions of Fibre sizes, this technology deals with the important demand for consistency in manufacturing requirements.

Significance of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is crucial in the field of optical Fibre modern technology, as it straight affects the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and overall transmission efficiency. Accuracy in gauging Fibre Diameter ensures that the optical properties are maintained within defined resistances, which is important for optimal signal honesty.

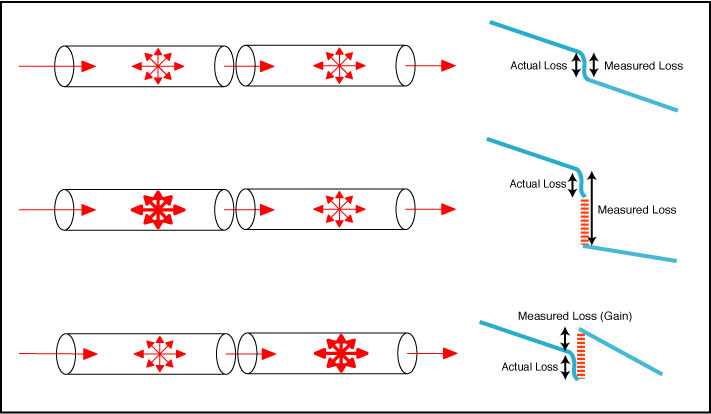

Variants in Fibre Diameter can bring about boosted losses due to spreading and modal diffusion, affecting the quality of information transmission. In high-speed communication systems, such discrepancies can cause substantial deterioration of signal quality, bring about information errors and lowered efficiency. Consistent Fibre Diameter is crucial for compatibility with ports and splicing technologies, which are important parts of Fibre optic networks.

Quality control procedures in Fibre production greatly depend on accurate Diameter dimensions to guarantee conformity with industry criteria. By executing robust measurement strategies, producers can boost product dependability, minimize waste, and enhance total system performance. Therefore, the importance of Fibre Diameter measurement can not be overemphasized, as it works as a foundation in the innovation of optical Fibre modern technology and its applications in modern interaction networks.

Just How the Analyser Works

The efficient dimension of Fibre Diameter relies upon innovative analytical strategies that ensure precision and dependability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser modern technology and advanced photo processing algorithms to precisely analyze the Diameter of fibres as they are produced

At first, a laser light beam is routed at the relocating Fibre, creating a cross-sectional shadow. The analyser catches this shadow utilizing high-resolution cameras positioned strategically along the production line. The caught pictures are after that refined in real-time to establish the Fibre's Diameter with extraordinary accuracy.

The system uses advanced formulas that represent numerous aspects, consisting of variants in light strength and ecological problems, to improve measurement dependability. It can discover minute modifications in Diameter, such as changes that might occur during the manufacturing procedure.

Furthermore, the analyser is capable of handling numerous fibers concurrently, enhancing throughput without compromising precision. By offering instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays a critical function in maintaining stringent top quality control requirements, guaranteeing that the final item satisfies industry requirements and client requirements.

Advantages of Real-Time Monitoring

While typical techniques of keeping track of Fibre Diameter often entail lengthy post-production checks, real-time surveillance substantially enhances the performance and quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive method permits makers to identify variances in Fibre Diameter as they occur, instead of waiting till production is full to evaluate top quality

By continuously gauging the Diameter throughout manufacturing, manufacturers can make certain that the fibres satisfy stringent specs, bring about decreased irregularity and improved consistency. Real-time surveillance also allows prompt corrective actions to be taken, lessening waste and preventing malfunctioning fibres from getting in the supply chain.

Furthermore, this innovation assists in enhanced information collection and his explanation analysis, offering insights right into manufacturing trends and potential areas for improvement. Such data-driven decision-making empowers makers to maximize procedures and keep high standards view website of quality assurance.

On top of that, real-time tracking cultivates a society of continual improvement within the production environment. Employees are much more engaged when they can see the effect of their work in real-time, causing heightened responsibility and a commitment to excellence. In general, the application of real-time tracking systems in optical Fibre manufacturing translates to superior product quality and enhanced client contentment.

Influence on Manufacturing Effectiveness

Carrying out optical Fibre Diameter analysers considerably enhances manufacturing performance by enhancing the production procedure. These gadgets assist in continuous surveillance of Fibre Diameter, allowing manufacturers to detect deviations in real-time. By identifying disparities without delay, production lines can be changed promptly, decreasing downtime and lowering the probability of producing malfunctioning products.

Moreover, the assimilation of these analysers right into the production operations allows better source allotment. With accurate Diameter measurements, operators can enhance material use, guaranteeing that resources are not lost on flawed fibers. This precision additionally contributes to less junk and remodel, inevitably reducing manufacturing expenses.

The automation given by optical Fibre Diameter analysers reduces dependence on manual inspections, which are vulnerable and typically taxing to human error. Therefore, employees can concentrate on even more strategic jobs, enhancing total performance.

Additionally, the information generated from these analysers can notify process renovations and promote far better decision-making. By evaluating patterns Click This Link in Fibre Diameter variants, producers can carry out positive actions to enhance production methods and maintain consistent quality. In summary, optical Fibre Diameter analysers play a crucial function in improving production effectiveness, causing higher quality output and raised profitability.

Case Research Studies and Success Stories

Throughout different sectors, study highlight the transformative influence of optical Fibre Diameter analysers on manufacturing procedures. One noticeable instance is a leading telecommunications company that faced challenges with irregular Fibre diameters, resulting in enhanced being rejected prices. By incorporating an optical Fibre Diameter analyser, the company achieved real-time monitoring of Fibre measurements, causing a 30% reduction in problems and significant price financial savings.

Furthermore, a research study organization concentrating on advanced products used optical Fibre Diameter analysers to refine their experimental procedures. The analyser's capability to offer comprehensive insights into Fibre uniformity allowed the growth of ingenious products with improved performance features.

These success stories highlight the essential duty of optical Fibre Diameter analysers in boosting quality assurance, boosting manufacturing efficiency, and driving technology across diverse markets.

Verdict

In conclusion, the Optical Fibre Diameter Analyser plays a crucial duty in boosting top quality control within Fibre production. As demonstrated through various instance researches, the analyser confirms crucial for attaining superior product top quality in Fibre production.

The execution of optical Fibre Diameter analysers permitted for strict top quality control, guaranteeing that the generated fibres fulfilled exacting industry criteria.In conclusion, the Optical Fibre Diameter Analyser plays a crucial role in improving top quality control within Fibre production.